At Actionpoint, we created our Insight packaging review to make it easy for customers to tackle issues affecting the price and performance of their packaging. The aim is to identify every single inefficiency, hassle, and niggle, and then offer solutions to address them – saving costs, increasing productivity, promoting sustainability, and proving irresistible to consumers.

An Insight review focuses on one or more of a company’s 3 key packaging areas: efficiency, environmental impact, and design. This blog takes a deeper dive into the third area, a Design Insight, to explain what it’s all about.

Who is a Design Insight for?

Businesses that choose a Design Insight are primarily concerned with customer experience and/or packaging functionality. Their issues tend to be based around the following:

- New product: You have a new launch coming up and need new packaging designed from scratch.

- Branding: You’d like to re-brand your packaging, introduce branded packaging, improve brand perception, communicate values such as sustainability, or build reputation.

- Unboxing experience: You’re keen to create a memorable unboxing that makes customers feel good and leaves a lasting, positive impression of your brand.

- Design issues: You’re experiencing problems such as assembly/packing difficulties or boxes are bursting or tearing in transit. If your packaging doubles up for display purposes, it may be failing to perform – not showcasing goods to best advantage, not staying upright, or not aligned effectively with your brand.

- Quality/Supply issues: The quality/quantity of packaging you currently receive from your supplier is unreliable or steadily getting worse. You want to understand your packaging better so that you can ensure you get what you need, when you need it.

How a Design Insight works

The review takes a holistic view of your packaging processes from start to finish and is a highly collaborative experience. Your input is essential to achieve an accurate assessment and determine next steps to achieve the best results for your business.

1. Your operation

Whichever type of Insight review you choose, they all begin the same way: talking to you and your team so we can understand your packaging performance, usage, supply, priorities, and goals.

Insight works with and supports anyone who has responsibility for your packaging. This is why we encourage the involvement of business owners and those in charge of operations, purchasing, production, quality, warehouse management, marketing, and sustainability. Typically, these roles and departments experience the immediate benefits from a packaging review.

Samples of your existing packaging are taken for testing in laboratory conditions to identify exactly what you are being supplied. Customers are often in the dark when it comes to technical packaging requirements, so can be using packaging that is over or under product specification. This means they are needlessly using and paying for excessively strong and expensive materials, or they are using weaker and cheaper materials that are contributing towards high damage/return rates. Once the correct product specification is established it can be used in conjunction with the review’s findings to support any recommendations for change.

2. Your Design Insight review

We arrange with you a convenient day and time for a packaging specialist to visit your premises and conduct the review. During this tour, the specialist is accompanied by you (or another nominated individual or team) and your Actionpoint Packaging Improvement Specialist, so you can ask questions or clarify any points raised.

Based on your business operations, the Insight review identifies actions to take to meet your packaging objectives. Recommendations take into account your workforce, premises, layout, equipment, warehouse space, transportation, and packaging management approach. Suggestions are given to improve the look and performance of your packaging, make boxes as easy as possible to be assembled and packed, and reduce operational time and cost. You will undoubtedly learn a great deal on the day but there’s no need to memorise all the facts and tips. Findings are written up into a report, which you can keep and refer to at your leisure. Following the Insight review, a meeting is arranged to present the report, discuss the outcomes, and decide how you would like to proceed.

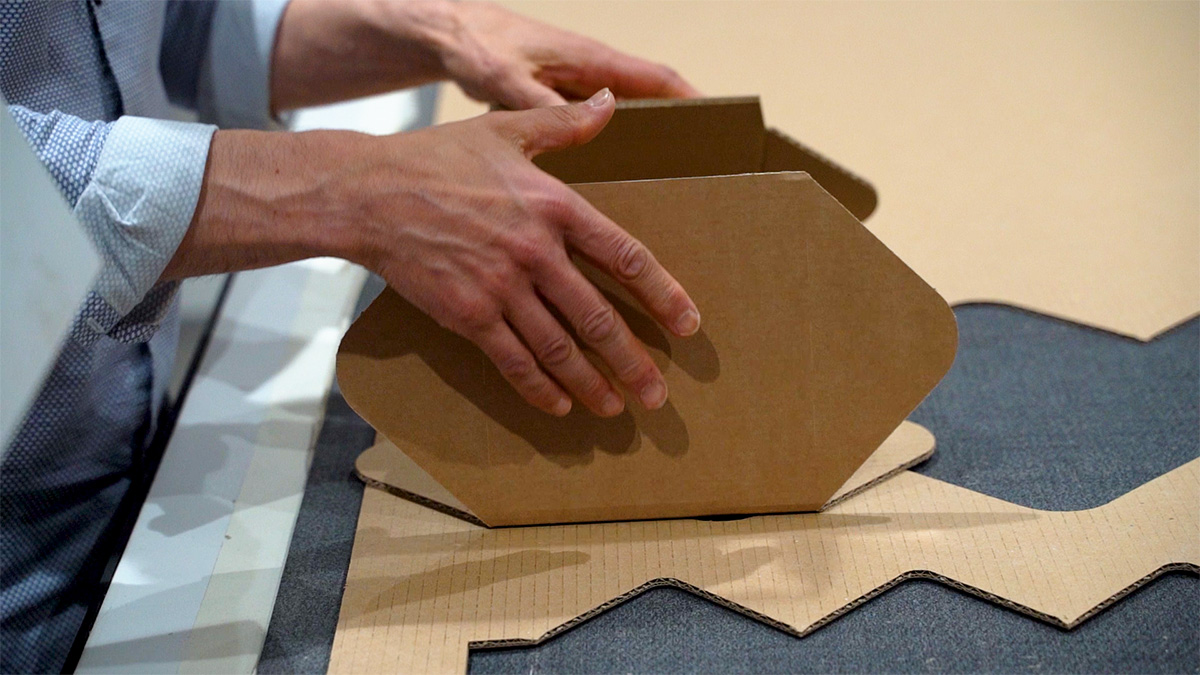

If you choose to go ahead with the Design Insight’s recommendations, a sample of the physical packaging product can be produced within 24 hours; or up to 3 days for intricately tailored work including the technical drawings and construction and trialling of the sample.

For samples of print branding, we can produce 2D or 3D mock-ups of conceptual artwork as a PDF that you can check on screen. We ensure the correct dimensions and format for print, Pantone colour match, gloss UV coating, and more to make sure it’s ready for manufacture.

3. Your solutions

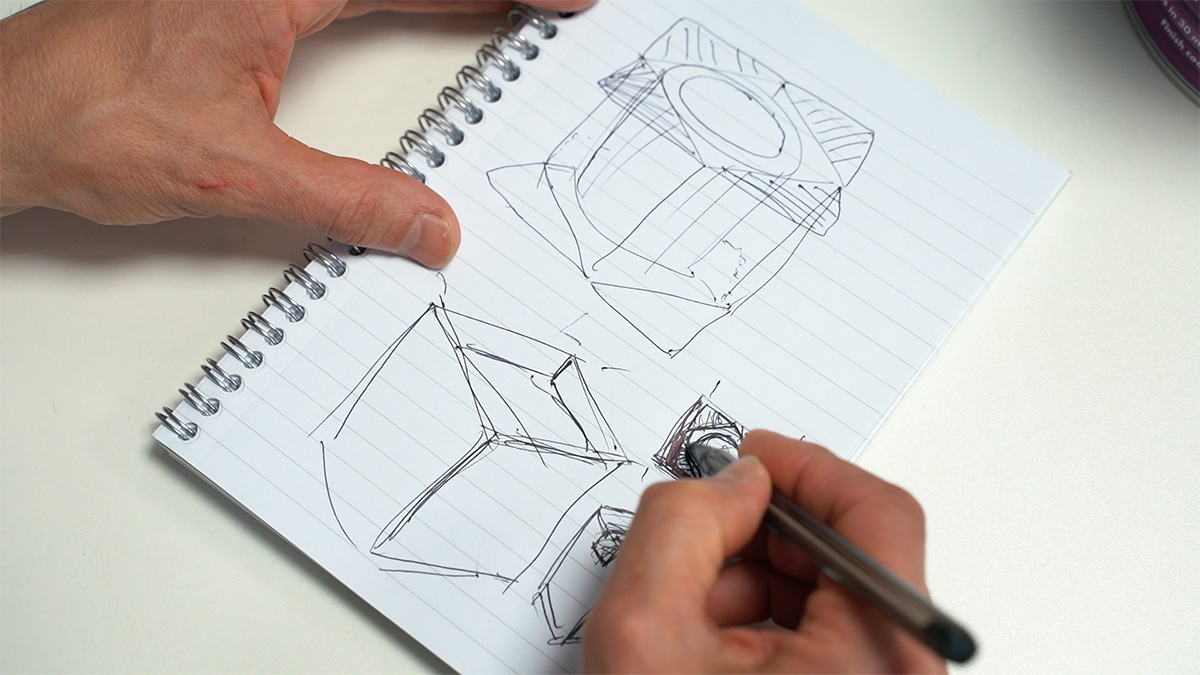

All the information gathered is shared with our Creative Team, so they can design your personalised packaging concept. Nothing is left to chance as they consider how the packaging will open, how the structure will unfold, how the product will be displayed, and how the print or ‘story’ will be revealed on the inside.

Materials are selected based on your brand, vision, product type and value, and environment for storage, delivery, or export. This may require double walled pierce- or crush-resistant substrate; or an attractive solution suitable for in-store display. Brand values such as sustainability can be encapsulated by materials that are 100% recyclable, 100% vegan, and manufactured in the UK to reduce carbon footprint.

Often, a Design Insight will entail an appointment at our state-of-the-art Packaging Creation Lounge. This is where you get to work closely with our in-house designers and gain a real ownership of your packaging. At the Lounge, you are involved at every stage from initial design and build to trialling the prototype. You can experiment with the positioning of your print branding until you’re happy with it. And, at the end of your appointment, you leave with a tested sample of your packaging to take away with you.

In addition to tests in our packaging trial room, we can run digital Box Compression Test (BCT) simulations using our in-house software. We also work with International Safe Transit Association (ISTA)-approved laboratories so we can offer BCT corrugated testing, transit testing, drop testing, and humidity testing, to give our customers extra peace of mind.

Next steps

The beauty of Insight reviews is they solve the packaging problems you know about and the ones you don’t. For example, you may have flagged your damage rates or use of plastic packaging for attention, but not realised that, with a few tweaks, your packing times could be much faster.

A Design Insight does all this and more: it takes bespoke packaging to the next level. Your packaging is not only tailored to your products and brand, but also to integrate seamlessly with your premises, practices, and team. Added to this, we have greatly accelerated the custom packaging process. Traditionally, personalised solutions take weeks from initial discussions to creation of a physical sample. At Actionpoint, we can have a prototype ready for you within 24 hours – or same day for Packaging Creation Lounge appointments.

Contact us to find out more about our Insight programme and how a packaging review could help your business.