For decades, it made sense for companies to buy goods from China. Low costs, high manufacturing capabilities, and a reliable supply chain were a potent combination. But that was in the past. Now, working with such a distant supplier can be fraught with worry.

Shifting geopolitics and environmental issues have cast a shadow over an offshoring strategy. But businesses buying abroad don’t have to remain in limbo and uncertainty. They can seize greater control by switching to onshoring – that is, by moving their packaging production back to the UK.

Why are companies worried – and why now?

The change in attitude isn’t recent; unease has been growing for some time. Not only because of the rising costs and increased carbon footprint when sourcing from China, but also ethical factors such as the country’s human rights record. Concerns ramped up in 2022 when Russia invaded Ukraine, and companies had to navigate catastrophic disruption to global supply chains. Plus, with China’s support of Russia during the conflict, there was the risk of reputational damage to businesses with Chinese-made or -supplied products.

In 2025, the risks of international trading came to a head once again with the United States’ headline-grabbing tariffs on imported goods. As of April, all countries must pay an additional 10% import tax, apart from around 60, which have personalised tariffs. In the latter case, their import tax is based on trade deficit – the difference between how much the country buys from and sells to the USA. At time of writing this blog, the UK has been allocated the baseline 10% tariff, while China is in a class of its own, at 145%.

With such steep US tariffs, Chinese manufacturers could struggle to trade, leading to factory closures or reduced capacity. It’s likely they will increase their prices to other customers to make up for lost revenue. For UK companies, that means a strong possibility of limited availability and higher costs. Organisations not already making changes to their packaging supply would be advised to start discussions at boardroom level and the sooner, the better. When disruption hits, there might be little time to react.

What are the risks of buying packaging from China?

Businesses whose packaging is shipped from China or the Far East will have a list of challenges:

- Long lead times. Packaging takes around three months to arrive. That’s a long time to wait, especially if there are delays in transit or at customs, or your packaging reserves are running low.

- Quality issues. If product quality is poor on arrival, you’re looking at another long delay for replacement. Plus, even the highest-quality packaging can be damaged during weeks at sea.

- Raw material costs. Although raw material prices aren’t currently spiking in China, there is uncertainty on what the Chinese government might impose on raw materials made or imported into China.

- Eco impact. Transporting your packaging across the world generates far higher emissions than working with a UK supplier. If sustainability is one of your brand values, then it’s time to bring operations closer to home.

- Geopolitical risk. As we have already seen, international tensions can give rise to conflict, sanctions, trade wars, and other restrictions, with serious consequences for your packaging flow.

What’s the difference between onshoring and nearshoring?

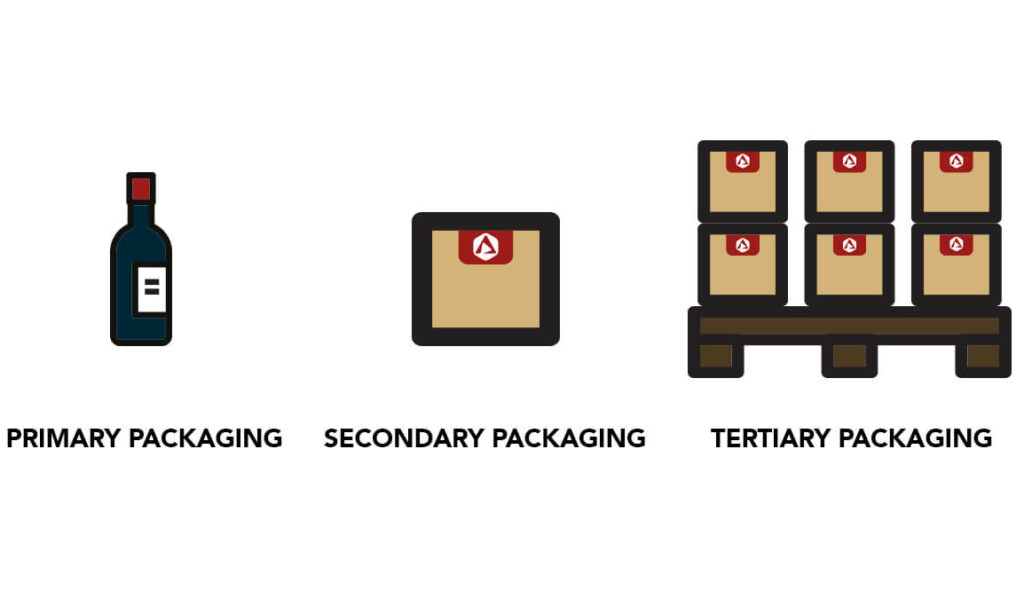

Onshoring means sourcing your packaging from the country where your business is based, in this case the UK. Nearshoring is when you source from a location closer to your country of operation, so you might choose somewhere in Eastern Europe. Whichever you decide on, the benefits are easy to see: shorter lead times, greater control, and smaller carbon footprint – all the while protecting your supply from future shocks.

What are the pitfalls of moving from offshoring to onshoring?

Anytime you change your packaging supplier, whether they’re based in China or Chatham, there are certain points you need to bear in mind:

- Check the spec

Whatever the specification is on paper, the reality is often different. We find that one factory varies from another, and this is exacerbated when offshoring as foreign countries work to different regulations. Ask your new supplier to test the packaging for a true specification.

- Prioritise your packaging

A company swapping from offshoring to onshoring will do a lot of planning. They consider how to move their production line, staffing requirements, and so on. Often the packaging is the last thing to be considered. But if you haven’t got your packaging, you can’t ship your products. Keep packaging high up on your list of priorities.

- Make adjustments

Certain types of packaging that can be made in China aren’t so easy to replicate in the UK. And you might not want to. Packaging that needs to withstand high or low temperatures, moisture, and vibrations on the long journey from China has very different requirements to packaging travelling a matter of hours within the UK. You may need to adapt the design and/or materials to suit the new arrangements.

- Invest in tooling

To make a new packaging design there’s an upfront cost: tooling. Manufacturers create customised cutting dies and printing plates, which can’t simply be handed over to the new supplier. You may need to invest in new tooling, but if you plan ahead, you’ve got a better chance of negotiating a rebate or support.

Tips for a smoother transition

Now you know the benefits and risks, here are our top 4 tips to make the changeover to onshoring as easy as possible:

Start early: think strategically rather than reactively. Don’t wait until disaster forces your hand. Even if you’re not likely to make changes anytime soon, understanding your options now keeps you agile for faster decision making when it counts.

Review your packaging: identify which stock-keeping units (SKUs) are critical and which are underperforming. If your packaging is overdue an audit, you may find you have more SKUs than you need and there’s an opportunity to rationalise and make savings.

Redesign for flexibility: small changes can make production easier as well as drive efficiencies, such as packing times, to boost your bottom line. Innovations come thick and fast in the packaging industry; take advantage of the chance to improve.

Work with experts: make sure your new supplier has the expertise to help you with accurate specs, tooling options, optimal lead times, and any other concerns you may have such as quality or storage.

How Actionpoint can help

As your packaging partner, Actionpoint offers more than just a box. We can guide you through the transition to make it as easy and stress-free as possible. Our team will work with you on aspects such as:

- Packaging redesign to optimise production

- Managing tooling, prototyping, and testing

- Timelines, regulations, and logistics such as stockholding

- Balancing cost, performance, and sustainability

Events in recent years have shown the cracks in the global supply chain. Offshoring, especially from China, has fewer gains than before and comes with growing uncertainty. Switching to onshoring or nearshoring will help to futureproof your packaging supply.

Whether you’re already exploring these strategies or have any questions on how they would affect your circumstances, our team of experts are here to help. Contact us today to find out more.