We all know the saying ‘You get what you pay for,’ but is that really the case with your packaging? If you want to save money, it seems obvious to pick the cheapest option such as the good old standard cardboard box. It costs significantly less than, say, a crash-lock cardboard box.

But things are never straightforward when you take a closer look. After all, you would hardly choose a pair of paper shoes over others simply because of the price. You’d consider things like comfort, durability, style, and crucially, water-resistance.

In this blog, we talk about the key differences between a crash-lock box (also known as auto-lock or self-locking box) and a standard cardboard box – known in the trade as a FEFCO 0201 box, or just an 0201. The FEFCO system, by the way, is very useful, as it allows us to refer to specific types of corrugated and solid board packaging by a simple code, instead of having to use long, unwieldy descriptions. And, better yet, it is recognised worldwide.

So, let’s read on; it’s time to decide for yourself if the upfront price tag is worth the long-term cost.

Why the price difference?

The main reason that an 0201 is so much cheaper than a crash-lock box is because of the way it’s made: it can be produced in just one process. And generally, the more processes of manufacture needed to make something, the bigger the cost.

To make a standard cardboard box, corrugated boards are made at a board mill, taken to a box-making factory, and fed into a casemaker machine. The machine turns each single board into a box; cutting the board to size, making the slots that create the flaps, and forming creases where the folds will be made. It applies a strip of glue to the end flap and, finally, folds and squeezes the cardboard to seal the glue.

The casemaker does all these processes automatically – and can add print if required. There’s no manual handling involved nor any need to switch to another machine. You put the board in one end of the machine and the box comes out of the other.

One of these machines runs around 12,000-15,000 boxes an hour.

The first process for a crash-lock box, or any box with a combination of flaps and indentations, is to go through a die-cutting machine to cut out the required shape. Process number two is placing the boards by hand into another machine, which applies glue to three different points, folds the box, and applies pressure to seal the glue.

To add printing to the boxes usually requires a third process: assembly workers feeding the boxes into another, separate, machine.

So, altogether, a box-making factory produces approximately 6,000-8,000 crash-lock boxes an hour.

Working hard or hardly working

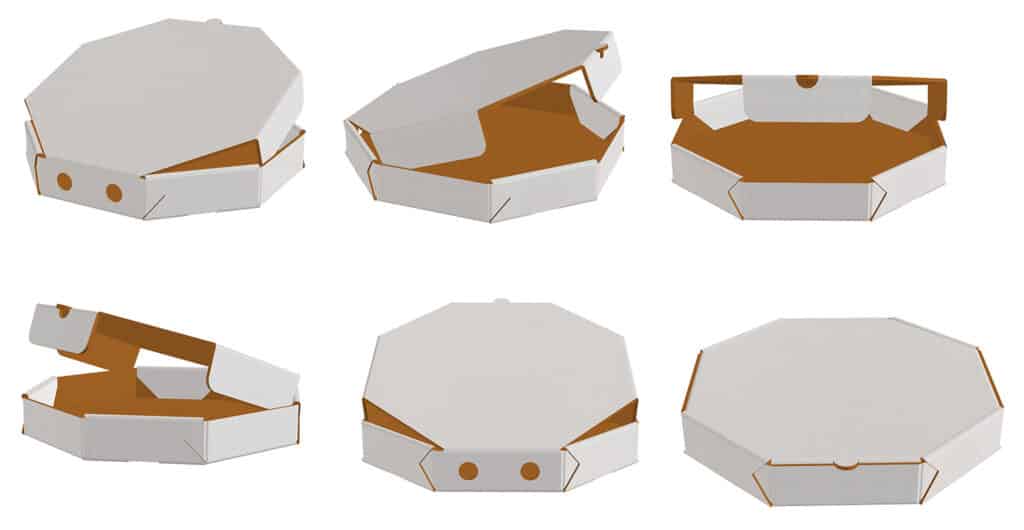

Both types of boxes are delivered flat-packed for efficient use of delivery and storage space. So far, so good. In theory, you could arrange to have them pre-assembled, but with a standard box the additional charge would negate the point of choosing a low-cost option, and with a crash-lock it really isn’t necessary because they are so quick and easy to use.

There’s no two ways about it, assembling an 0201 standard box requires a lot of effort. You take the flat-packed box and open it up to create the box shape; then, making sure the bottom of the box is facing upwards, fold down the two smaller flaps; next, fold the larger flaps and, making sure they’re lined up neatly, apply tape to secure them in position.

You may want to put several strips of tape along the join of the flaps, up the sides of the box, and even on the edges to be certain the box will protect your goods. Now you can flip the box over, so the base is on the floor. Fill the box with your product(s) and add voidfill or cushioning of your choice to prevent movement during transit. Finally, secure the top of the box in the same way as described above.

That description probably felt like it took a long time to read. To actually do it, takes even longer.

Now grab a flat-packed crash-lock box. Gently push the opposite corners of the box together. It will spring into shape and lock the base into position in a single action. Within seconds you can place your goods in the box, add voidfill, then close the hinged lid and securely fasten using the integrated ‘peel and seal’ adhesive strip.

The need for speed

The name ‘crash-lock’ refers to the base of the box locking into place at great speed. And clearly crash-lock boxes have the edge when it comes to fast assembly. This could translate to considerably more boxes getting packed per session or fewer packing workers required to do the same job.

There is little to no training required for assembly, and crash-lock boxes reduce the risk of RSI because they are so much less labour-intensive. They also eliminate the need for packing tape – a time-consuming process whether applying tape, replacing empty tape on a dispenser, or keeping the packing area tidy.

So, what’s the catch – does this mean that crash-lock boxes are fast but flimsy? Actually, no. In fact, they are far stronger than a standard box. The pre-glued flaps overlap and lock together to form a thicker, extra durable base that makes these boxes suitable for a wide range of products.

If presentation is important to you, crash-lock boxes also guarantee uniform, high-quality results with your packaging every time. Standard boxes rely more heavily on the ability of the packers, which can vary from one person to another. Plus, they may not get the best results if they are short-staffed, agency workers, or focused on quantity over quality.

Filling the void

A standard box is adequate for basic packaging if you’re looking for the lowest price tag and it doesn’t really matter how your product is presented. There are boxes available with creases for multi-depth options, which you can fold down to better match the size of your product. But bear in mind this will add to your valuable packing time and does look messy. You will still need to use a lot of voidfill and packing tape to give your products the chance to arrive at their destination intact.

A crash-lock box offers strong protection plus a wow factor for the recipient. The idea is to use a personalised size to fit the contents very closely, whether that’s an individual product or multiple items such as a gift set. Bespoke corrugated fitments can also be added to protect fragile products, preventing them from rolling around in transit, while adding to the presentation of the goods.

Crash-lock boxes are perfect to work in sync with attractive voidfill and cushioning to enhance the unboxing experience. There’s a raft of options including coloured crinkled or shredded paper, tissue paper, specialist paper padding or cushioning systems, bubblewrap rolls or pouches (including biodegradable or paper bubblewrap), foam cushioning, packing peanuts, and corn starch based loosefill.

There are also air cushions, or air pillows, which are available in recyclable versions – meaning they can be recycled after use – or recycled versions that are actually made of recycled material. It’s useful to know the difference, as plastic packaging containing 30% recycled plastic avoids being stung for Plastic Packaging Tax.

Better by design

A standard cardboard box, by its very nature, does not have any bells and whistles. What you see is what you get. The basic structure is quite weak, so needs to be made of corrugated cardboard with larger fluting to give it more stability. This fluting is what gives corrugated cardboard its name, referring to the wavy – or corrugated – layer in the middle of each sheet of cardboard.

On the plus side, the low cost of an 0201 means it is an economical first step on the packaging rung for businesses just getting started. A standard box is also a good container for other boxes, fits nicely on a pallet, and is handy for transit packaging or B2B organisations where presentation is not a major concern.

Crash-lock box design is much smarter. It has an integrated open-tear strip, so the end-user can quickly open the package with ease. No fuss or fumbling or scissors required. And you can use smaller fluting because the box is already so strong. Smaller fluting is less costly and less bulky – so you can fit more on a pallet and use your storage and delivery vehicle space more efficiently – and it works much better as a print surface giving a nicer finish.

Custom packaging embellishments can easily be added to a crash-lock box, such as specialised cut-outs, cardboard flourishes (think of pop-up books), or to strengthen the base even further for particularly heavy items.

Printed branding and graphics can be used on both standard and crash-lock boxes, such as company logos, designs, transit or delivery instructions, and other useful information. The difference is that branding looks more mundane on an 0201. Whereas the way a crash-lock box opens allows you to place the print in exactly the right places for a stunning unboxing. A standard box simply can’t compete in terms of a first impression.

For high volumes of printed branding, flexographic printing is a popular, fast, and economical choice for both standard and crash-lock boxes, with digital printing advised for smaller quantities. Some high-end products use a premium and more expensive lithographic print for a crash-lock box, but the cost renders it unsuitable for standard boxes where the whole point is to keep the price low.

At the moment there is a bit of a trend for packaging with an ‘earthy feel’. Plain brown kraft paper is used on the outside to provide a pleasing contrast with the burst of colours, customised fitments, and flourishes on the inside, really ramping up the unboxing appeal. Inserts further build on the customer’s experience and brand loyalty with discount offers, product samples, small gifts, or a simple thank you note.

A plain exterior may also be worth considering for another reason – for those well-known brands whose parcels may be left unattended on a doorstep and contents identified by a third party.

Many happy returns

As we’ve already outlined, there are many ways to reduce the risk of damages, however there will always be the occasional mishap. Or perhaps the item was faulty to begin with, or the wrong type or size was packed. The next step is for the customer to return the item. At this stage they will probably be annoyed – no one likes hassle – so the best way to keep customers on side is to make the returns process as easy as possible.

Crash-lock boxes can be used as a returns box if needed. They can feature a secondary ‘peel and seal’ strip on the lid, so it is quick and simple to securely package returns. Standard 0201 boxes, on the other hand, will have been weakened from their initial journey and being opened by the recipient. If they are reused for return shipment, it’s likely the customer will have to use a lot of packaging tape.

Eco-friendly packaging

Both standard boxes and crash-lock boxes are predominantly made of biodegradable cardboard and so they are straightforward to flatten and put in the recycling bin. But let’s not forget about that packing tape, which introduces plastics and solvents into the environment and of course carbon emissions from manufacture and delivery. Not to mention noise issues in the packing area from countless tape dispensers or sealing machinery doing their work.

Crash-lock boxes have the edge because they don’t use tape. The same box can conveniently be repurposed for returns and, again, no tape is required. The recycling process is easier because there is no tape to pull off before recycling. Added to this, crash-lock boxes use starch-based glue which is simple to remove. When the box is repulped, it’s put into hot water and boiled. All the glues – and any inks from print branding – float to the top and get skimmed off so when the water is drained, you’re left with pure paper pulp.

Who uses crash-lock boxes?

Typically, a B2C business model – such as one in the hair and beauty, medical, health, or food industry – is an especially good fit for a crash-lock box, because the goods are arriving secure and looking impressive when they do. High-end gifting such as premium fudge and biscuits present exceptionally well in the attractive packaging, while heavier items like luxury candles in glass jars gain extra support from the sturdy base of the box. But it’s fair to say most businesses selling products online could benefit from using this style of box.

For example, if you’re in an environment with a high volume of products, packing time per parcel is critical. Crash-lock boxes speed up the process considerably whether packing by machine or by hand. They can mean the difference between packing 100 boxes a day to 1,000.

Making your mind up

When it comes to a packaging strategy it’s worth doing your homework or speaking to an expert to make sure you’re getting the best value.

With time-saving solutions such as crash-lock boxes, you can ease two of the most pressing issues of the day: labour shortages and increasingly demanding customers – who are expecting faster deliveries, quality presentation, eco-friendly credentials, and of course for their purchase to arrive in pristine condition; and who are quick to change to alternative suppliers if these expectations aren’t met.

If you’re not sure that crash-lock boxes are suitable for your business, contact your packaging supplier. They’ll be able to advise you on this along with a range of related matters such as bespoke packaging solutions, materials, cushioning, Plastic Packaging Tax, sustainable packaging alternatives, and storage considerations.