When is a cheap box not a cheap box? A guide to Total Cost of Ownership

In the face of rising costs and uncertainty, it’s tempting to reach for the least expensive box on the shelf. But a low upfront cost can mask a range of hidden expenses. Instead, it’s worth taking a Total Cost of Ownership (TCO) approach.

The basic concept of TCO is simple. It’s often explained using a puppy example: you could adopt a rescue puppy for free (or a nominal donation), but over the pup’s lifetime the total cost of ownership – food, supplies, healthcare, and so on – will be considerably more.

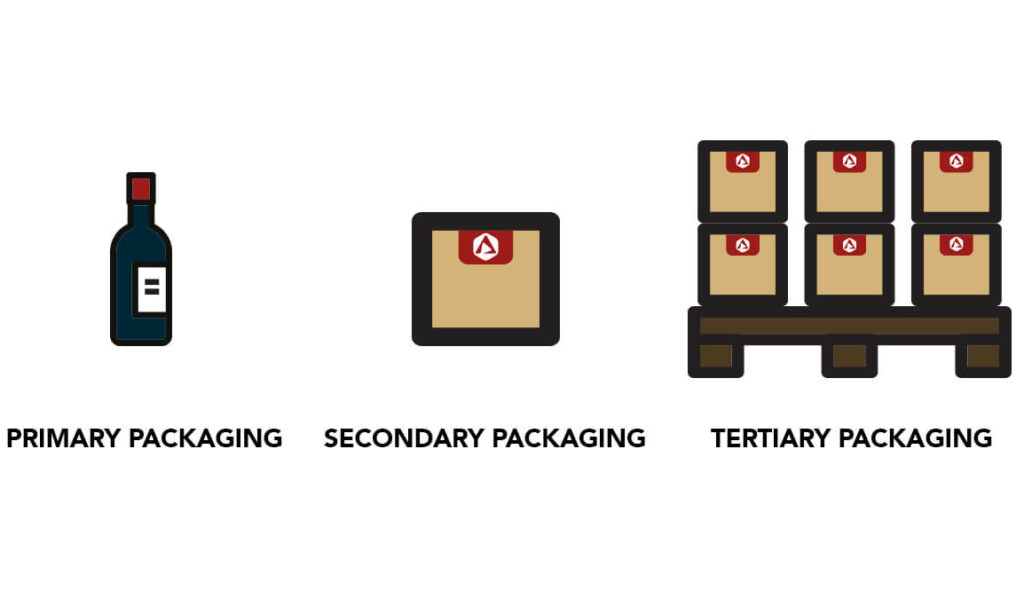

Packaging TCO factors in the full lifecycle from box purchase and packing to storage, shipping, and disposal. And with the UK’s Extended Producer Responsibility (EPR) for packaging fees due from October 2025, understanding TCO isn’t just smart, it’s a financial necessity.

The real cost of cheaper packaging

Lower-priced packaging usually costs less because it’s a mass-produced, generic item rather than tailored to your goods. Its materials and design are standard. They don’t consider your product’s weight, or features that are particularly fragile or sharp, or any risks of leakage or contamination. Because the packaging is inherently unsuitable, packers try to compensate by using copious amounts of voidfill, stretch wrap, and tape.

This is where the hidden costs start to accumulate:

- Packing time and labour: If it takes longer to prepare each order, labour costs rise, and fewer goods leave the warehouse.

- Protective materials: Extra fillers, bubblewrap, tape, stretchfilm, or cushioning may seem minor, but over thousands of shipments, the expense adds up.

- Palletisation efficiency: Inefficient pallet use wastes space, increases transport costs, and raises the risk of damage or injury.

- Storage and warehouse logistics: Bulky or awkward packaging consumes valuable warehouse space and slows down operations.

- Product damage and returns: Poor protection increases the likelihood of breakages, returns, and replacement costs.

- Environmental fees: Taxes and regulations such as EPR penalise unsustainable materials by imposing higher fees.

- Brand reputation: Packaging that fails customers (through damage, waste, or lack of recyclability) can harm your reputation and reduce future custom.

A false economy

A lower purchase price doesn’t always translate to lower overall spend, as this snapshot illustrates:

Packaging factor | Box A (50p) – generic | Box B (60p) – bespoke |

Packing speed | Slower | Faster |

Risk of damage | Higher | Lower |

Pallet efficiency | Poor | Optimised |

Waste/recycling cost | Higher | Lower |

Sustainability rating | Low | High |

Total cost | 75p | 67p |

At first glance, off-the-shelf box A looks like the cheapest solution. In reality, it’s bespoke box B. Thanks to its superior operational and environmental performance, the total cost is reduced. But how does this play out in the real world? Let’s take a look at two Actionpoint case studies.

Small changes, big savings

For Hochiki Europe, a leader in life safety products, the goal was to use less plastic in their packaging. Actionpoint assessed Hochiki’s operation and recommended updating their voidfill systems. The new paper voidfill machines used less material, improved packaging performance, and sped up packing stations. Added to this, plastic tape was replaced with paper tape. These outwardly small changes drove significant time savings and decreased plastic packaging and waste.

The total impact? Over £17,000 saved annually, plus a clear boost to Hochiki’s sustainability credentials.

Design smarter, ship faster

Another key TCO factor is pallet efficiency. With more units per pallet, you ship more product while reducing logistics costs and eco impact. Switchee, a provider of smart home technology for social housing, faced this exact challenge. Actionpoint’s team designed a smaller, stronger box made from recycled materials. The new packaging was 84% more efficient on pallets, used 23% less cardboard, and simplified the packing process.

Once again, this wasn’t about buying the cheapest box, it was about choosing the best-performing solution for the bigger picture.

EPR and TCO

One key factor pushing up TCO is the introduction of Extended Producer Responsibility. For the first time, packaging producers are being forced to bear the entire financial burden of packaging waste. In December 2024, DEFRA said it anticipated EPR to cost UK industry around £1.5 billion (although the British Retail Consortium estimates £2 billion). Marks and Spencer alone is looking at payments in the region of £40 million. As retailers and manufacturers scramble to pay the new fees, some will have to raise their prices. The Bank of England has already noted increases in food prices in anticipation of EPR and expects more towards the end of the year.

EPR highlights how custom packaging design can be used to lower TCO. With bespoke, recyclable, lightweight packaging, companies have the power to shrink their carbon footprint and EPR fees.

How Actionpoint can help

After 50 years of developing personalised packaging solutions for a wide range of manufacturers, we have the skills to:

1. Identify hidden costs. Our Insight packaging reviews uncover inefficiencies throughout the packaging process.

2. Optimise materials and design. Our solutions reduce waste, improve packing times, and boost pallet efficiency.

3. Make sustainability-driven choices. We offer recycled, FSC®-certified (FSC® C186587), and low-carbon materials that decrease environmental fees and support your goals. These are available on request.

4. Integrate smart equipment and automation. Our recommendations streamline workflows to improve performance, quality, and speed.

Start making packaging savings

Contact our team today so that we can identify all the elements driving up your packaging’s total cost of ownership. Together, we’ll create a tailored packaging strategy that allows your business to grow.

Sources:

TCO explained: https://assets.publishing.service.gov.uk/media/5a78c45c40f0b6324769a030/Total-Cost-of-Ownership-things-to-consider-v1.pdf

EPR due October: https://www.gov.uk/guidance/extended-producer-responsibility-for-packaging-recycling-obligations-and-waste-disposal-fees

FEFCO 0201 vs crash lock box blog: https://actionpoint.co.uk/standard-cardboard-box-vs-crash-lock-box-which-is-best-for-me/

EPR blog: https://actionpoint.co.uk/extended-producer-responsibility-for-packaging-epr-2024-update/

Hochiki case study: https://actionpoint.co.uk/casestudy/hochiki-europe/

Switchee case study: https://actionpoint.co.uk/casestudy/switchee/

BRC estimates £2 billion EPR: https://brc.org.uk/media/2aljs1nz/ceo-letter-to-the-chancellor-budget-2024.pdf

M&S £40m EPR bill: https://www.ft.com/content/e5ed2e6e-0c00-4399-9acd-ac193a801623

BoE, EPR and food prices: https://www.bankofengland.co.uk/monetary-policy-report/2025/august-2025

Bespoke web page: https://actionpoint.co.uk/solutions/bespoke-packaging/

Insight web page: https://actionpoint.co.uk/solutions/insight-packaging-audit/

Contact us web page: https://actionpoint.co.uk/contact-us/