Businesses are continually looking at ways to improve their sales, profit, efficiencies, and product innovation. Unfortunately, packaging can slide down the list of priorities, even though it has the potential to be a fantastic asset or a major cost to your operation.

Pitfalls of Packaging Neglect

Have you ever stopped to think about why you do your packaging processes the way you do them? Often, it’s simply the way it’s always been done. And this is why packaging process reviews are so beneficial: they bring in a fresh pair of eyes. It’s easy to miss the obvious when your focus is elsewhere or you’re doing the same things day in, day out.

There are four common scenarios that can play out when packaging is overlooked.

1. Too Many Manufacturers

Over the years, you rack up a number of manufacturers for different elements of your packaging. This results in an assortment of boards and substrate, which vary in thicknesses and quality. The latter is especially pronounced with suppliers from other countries (or even if part of the supply chain is overseas) as they can work to different standards.

In this situation, you’re more likely to be buying in smaller volumes from each manufacturer. This pushes up the unit price and relegates you to a minor account with no purchasing power, so you are less likely to get the attention you deserve. There’s also a high administrative burden dealing with paperwork for every supplier, and you have to navigate multiple levels of advice as each business is there to sell their own product. Not to mention the impact it has on your carbon footprint.

2. Too Many SKUs

Every time a new product comes along, new packaging is commissioned. But none of the old stock-keeping units (SKUs) are reviewed or removed. Repeat orders continue to be made for old SKUs, and products are made to fit the packaging rather than the other way round.

Often, the old packaging SKUs are not even produced by the original manufacturer, meaning the paper grades may well have changed. So, money is being spent on – and storage space is taken up by – boxes that don’t match their original specification, and were designed to protect products that are no longer being made.

3. Poor Performance Becomes the Norm

Some damages are to be expected, but if no-one is monitoring breakages you could be losing money hand over fist. Take a look at how many boxes are being dropped by the courier, crushed in transit, or affected by damp or humidity. Now add the expense of having to deal with all of the damages: the additional customer service time, returns, goods replacement, packaging materials, assembly time, postage/delivery, carbon footprint, and reputational damage. You may be surprised by how much your packaging is really costing you.

4. Miss Out on Industry Advances

Packaging is an innovative sector. If yours hasn’t been reviewed for a while, you will have missed updates in materials and technology that have come on in leaps and bounds. A different design can use less packaging and reduce waste while improving packing speeds, box durability, and appeal. High performance materials continue to hit the market, and these are lighter, thinner, and come from sustainable sources or contain increasingly more recycled content.

Packaging Insights

A packaging audit dispels myths and gives you a better understanding of how your packaging works, so you can make the right purchasing decisions. Think you can’t use sustainable packaging because your goods are ‘too’ delicate, heavy, or bespoke? Or assume you can’t manage without foam or polystyrene? A review with a packaging expert can help you navigate a huge range of affordable eco-friendly packaging options – even for foam – and how to use them to best effect for your needs.

There are four main approaches to putting your packaging under the metaphorical microscope:

- Do it yourself. But do bear in mind you may not have the necessary skills in-house and it would be difficult to replicate an outsider perspective.

- Ask your current packaging supplier for help, especially if they have specialist knowledge or expertise in your industry.

- Contact a different packaging supplier for an audit. You don’t necessarily need to be an existing customer to request a packaging review, and it may be done free of charge.

- Hire an appropriate consultant with packaging expertise.

If you choose options 2-4, check beforehand that any findings are suggestions only. You shouldn’t be tied into making changes, it ought to be your choice whether or not to proceed with any or all of the recommendations.

Whichever method you select, there is a lot to consider during a packaging audit. See below some examples of what to look for within four key areas: specification, design, warehouse, and supplier.

1. Packaging Specification

One of the most important things to do is confirm the true specification (spec) of your current packaging. If it’s over-spec’d you could be buying expensive materials you don’t need, effectively using a sledgehammer to crack a nut. If it’s under-spec’d, you may be paying over the odds for inferior quality packaging.

You might even discover you are using many different types of board and you could manage perfectly well with just one for your cases and boxes. This would simplify packaging administration and storage and make significant savings.

Once you have an accurate spec, consider if there have been any changes in your operation since your packaging was first designed. For example, quantities, product range, method of transport, delivery destination (UK or abroad), or storage environment. Each of these could impact the performance and the cost of your packaging.

2. Packaging Design Issues

Packaging designed for goods you no longer make. Are you making your products fit the packaging or the packaging fit your products?

Materials are inadequate. For instance, boxes are being crushed on the pallet, pierced by their contents, or warping in transit.

Using virgin over recycled. Making your packaging more sustainable doesn’t have to be expensive. You can swap white paper for brown, Kraft paper for Test, or plastic or foam for paper or recycled equivalents. There is a sliding scale, too, so you can find materials with anything from 30% recycled content (in line with the Plastic Packaging Tax) up to 100%.

Too much bulk. A different design could reduce the overall box size, enabling more boxes to be stacked per pallet. Or it could lighten the weight to reduce postage/delivery costs.

Cost versus speed. To keep costs down, a low-priced design is selected without considering repercussions further down the line. A wrap style box is relatively inexpensive because it is not glued or stitched by the box manufacturer, but it does require more taping when it’s been packed. The price of a crash-lock box is higher, but it is assembled in seconds. Compare packaging costs with packing times and damage rates to make sure the design is the most cost-effective for your needs.

Lack of marketing. Packaging is the ultimate marketing tool, being delivered right into customers’ hands. Are you using yours effectively: engaging customers, sharing your sustainability journey, reflecting your values, and telling your brand story?

3. Warehouse Issue

Too much space used up with packaging, so there is not enough room for your own products or for your packing stations. Could you be more economical with the space and/or declutter the area? Perhaps you need to consolidate many different SKUs to a smaller range or introduce multi-depth boxes. And look into offsite stockholding options with next day delivery, which could unlock cost savings as well as warehouse space.

Poor packing efficiencies. Consider how easy and fast it is to assemble your boxes. Are creases ill-defined, is the board too rigid? Time taken to re-fold creases soon adds up. Dealing with excess waste material or applying copious amounts of voidfill or packing tape also impacts on productivity. A few packaging design tweaks could eliminate these problems and quickly have the assembly line fulfilling more orders.

Storage environment is not up to task. Check there are no leaks in the roof or walls, no bird nests overhead (and subsequent risk of droppings), and that the storage area is well maintained – no tattered or broken pallets, jutting nails, or anything else that may cause damage to boxes or products.

Boxes stacked and palletised incorrectly. Are they always stacked in the correct formation and, crucially, the right way up? Boxes must be positioned properly to benefit from the strength of the corrugations. Is pallet wrap being applied in the right way? If the tension is too loose, you may find that extra pallet wrap is being used to compensate. Issues like these can be resolved by training your warehouse operatives. Or you may find that changing to a different product, such as pre-stretched pallet wrap with higher tension, could solve the problem.

4. Supplier Issues

Lack of care and attention. Think about how big or small or important you are to your current supplier. This affects the quality of service/advice and even product that you get.

Same old, same old. If you always deal with the same type of supplier, you will always get the same message and assurance that what you are doing now is best for you. Perhaps consider an independent audit? Or speak with a supplier who is embracing the latest methods, materials, and technologies. Talk to companies or people who see how things are done by others in your industry, as well as cross-over industries that are packing similar types of products.

Business mismatch. Each supplier has their ‘sweet spot.’ Is your business a good fit with your current supplier’s capabilities and resources? If not, you are probably not getting the best overall solution and support.

Next steps

There are many reasons why packaging assessment takes a back seat. Perhaps, over time, there have been multiple staff changes in the purchasing department and it’s just easier to repeat the same packaging orders. Maybe your business is experiencing rapid growth and your attention is elsewhere trying to keep up. Conversely, your time could be consumed by cost-cutting measures due to the current climate. Or possibly you have a backlog of packaging that you don’t want to go to waste.

These reasons only highlight that a review is needed more than ever. And you only need to set aside a few hours with a packaging specialist to identify significant savings.

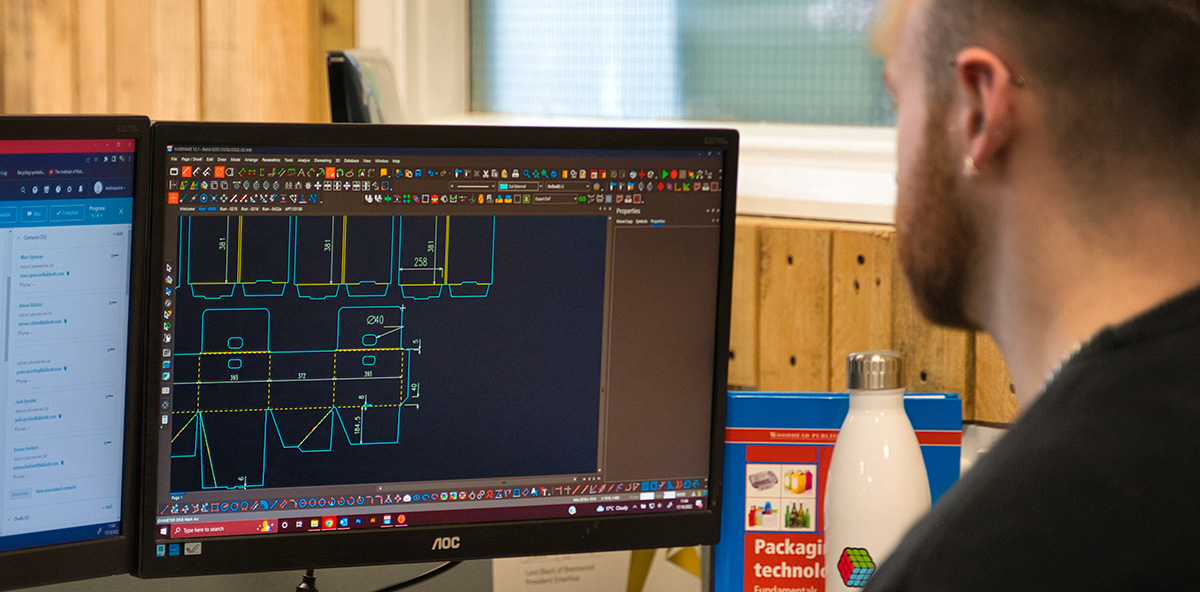

At Actionpoint, we offer our Insight packaging audit, which analyses your packaging processes, sustainability aims, warehouse workflow, and packaging supply chain and quality issues. Afterwards, you receive a comprehensive report revealing problem areas, hidden costs and how to tackle them, with an average cost saving of 17%. Meanwhile, our fully equipped Packaging Creation Lounge is the perfect place to test your packaging, make design tweaks, or create and trial a completely new solution – all in just one appointment with our in-house design team.