There are certain situations where it makes sense to do a packaging review. If it has been over 12 months since the last one, for instance, or if you are introducing new products to your range. But we have noticed that many successful businesses also look to their calendars. They tend to reassess their packaging and processes around February or March every year. This blog explains the reasons why they do it now and how you could benefit from this approach. Is your packaging due a check up?

Take a breath

Cast your mind back a couple of months and you’re likely to have experienced one of two things. Either December was an extremely busy month, and you spent January catching up, or the festive period was quiet and your operation ramped up in the New Year. Either way, by the time February comes around, there’s a chance to take a breath. This is the moment to check your packaging and packing systems, otherwise you could spend the next 6 to 12 months working inefficiently. Instead, find ways to increase output, reduce waste, and tackle damage rates for a truly productive year.

New financial year

Organisations use this time to set their budgets for the new financial year. When deciding your packaging spend, make sure that you are getting the best value for money. But this doesn’t just mean price checking. Investigate if you can reduce packaging size and weight, amend the style for faster packing, or swap out materials for less expensive ones. Explore the latest packaging innovations that are stronger, lighter, and more sustainable. Just a few tweaks could make your budget go further. But don’t forget to put in a buffer, protecting you against any price rises caused by unexpected disruptions in the supply chain.

Business plans

Packaging is not a standalone issue but integral to your business. When planning operational and strategic changes for the year, ensure you have considered how they will impact your packaging requirements. For example, changes to:

- Storage space. If you are going to move to a bigger warehouse, you could buy packaging in bulk, reducing the unit cost. Conversely, a decrease in storage space could leave you short of packaging when you really need it.

- Delivery destination. Perhaps you’re going to start exporting goods. If so, your current packaging may not be up to the task for hot, humid, or extremely cold temperatures.

- Delivery method. You need a specific type of packaging depending on means of transport. Courier packaging is designed to cope with knocks and drops in transit, while palletised boxes in a truck need specific box compression strength to prevent crushing.

- Stock Keeping Units. If you are introducing a new SKU, see if there are any others you can remove. Too many SKUs can be needlessly complicated and expensive to manage.

- Product line. When a product is taken out of the range, ensure the packaging is, too. If you continue using packaging designed for a different product, it won’t necessarily offer the same levels of protection or be optimised for your assembly line.

Packaging legislation

Q1 is an important time for focusing on packaging costs. Right now, companies are submitting their Extended Producer Responsibility (EPR) Jul-Dec 2024 packaging data for the 1st April deadline.

Next year, EPR fees will be modulated so the harder your packaging is to recycle, the higher the fee will be. Get ahead of the game by investigating ways to reduce your packaging’s eco impact – and budgeting for the necessary changes – to minimise EPR expense.

On a similar note, the UK Government’s Spring Budget is announced in March, and you can guarantee the Plastic Packaging Tax (PPT) will rise. Plan how you can reduce virgin plastics or use alternatives to help lower PPT payments.

Packaging suppliers

A packaging review would not be complete without mentioning your supplier. Even if you are generally satisfied with the service they provide, there could be room for improvement. Consult with the relevant members of your team and review your supplier’s packaging quality, customer service, order accuracy, and on-time deliveries in 2024.

Ask yourself if the packaging they currently supply is compatible with the level of growth you want to achieve. When your turnover climbs, your packaging needs to keep up. If you’re reaching capacity, you may be tempted to take on extra staff when all you really need is a more efficient packaging process.

Price hikes have been an issue in recent months and years. Think back and consider if your supplier gave you adequate warning and advised how to mitigate the cost. In fact, did they check in with you throughout the year – not just to take an order, but to see how you were or make suggestions for continuous improvement?

Finally, confirm how often they ran out of stock last year, and whether their sustainability goals still align with yours. Then schedule a catch up to talk about any concerns and/or investigate other suppliers that might be a better fit.

Packaging review basics

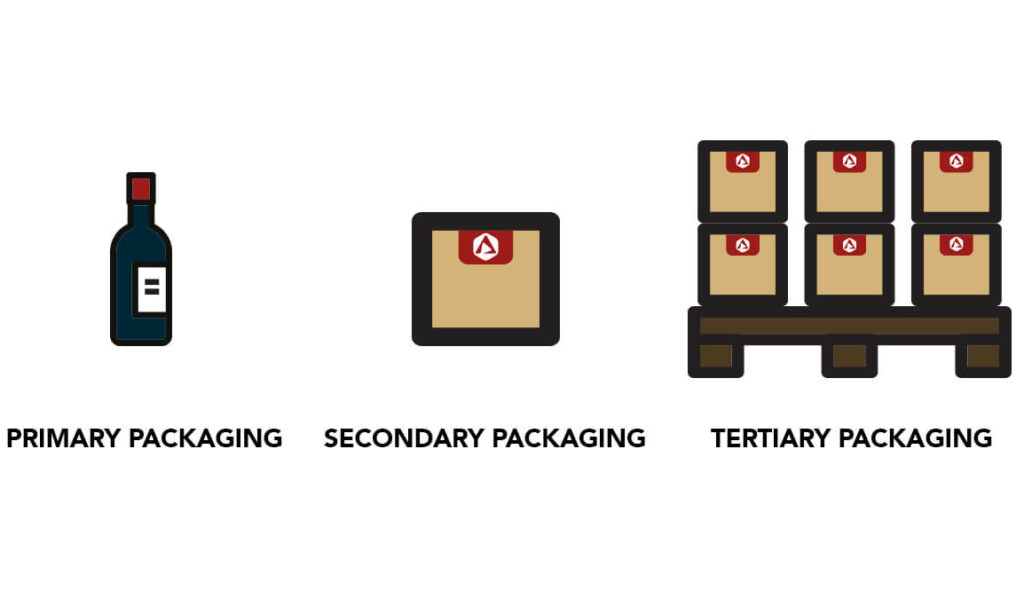

We’ve talked about why businesses do packaging reviews this time of year, but not about what it entails. In short, a review should assess the suitability of your packaging for your product, operation, and brand. The main 3 areas are:

- Protection.

The number one question: does it protect your product? If breakages are an issue – and increasing – that’s a red flag. Identify why this is the case and you’ll cut the costs of returns and reputational damage. The reasons could be anything from an outdated box design, inappropriate board material grade, or poor packing methods to improper stacking and storage.

- Efficiency.

The obvious place to start looking at efficiencies is packing times. A solution may take 1 minute 30 seconds to pack, when you could achieve 45 seconds with simple changes to packing stations and packaging design. And what about material costs? You may be paying for boxes that are far stronger than you could possibly need, at a correspondingly high price. Plus, packaging that is too big and heavy takes over more storage and transportation space, is more expensive to post, and generates more waste.

- Unboxing.

Does your packaging create the right impression for your customers? Complement high end goods with a carefully thought-out box-opening experience. Eliminate hassle with easy to open tear strips, and display products to their best advantage with bespoke packaging fitments or voidfill. See if there’s an opportunity to update or strengthen your brand’s story with appealing and memorable packaging that connects with customers.

How Actionpoint can help

It’s possible for you to conduct a packaging review yourself, but using someone with in-depth knowledge will help you to get the most out of it. One approach would be to talk to a packaging manufacturer but bear in mind they can only advise you based on the style of packaging they make. Ideally, find a specialist with broad expertise such as Actionpoint, which has access to many different materials and production lines.

You can also take advantage of our Insight packaging review service, which takes a holistic view of your packaging processes, including packaging design, efficiency, and environmental impact. It’s the quickest way to identify bottlenecks and hidden costs. Plus, we list all the actions you can take that we know from vast experience will improve performance.

Enjoy the comfort of our state-of-the-art Packaging Creation Lounge and try out new materials, designs, configurations, and voidfill options. Working with our award-winning in-house design team, you’ll see your custom packaging ideas come to life in just one appointment.

Contact our team today to find out how we can support your business for a more productive and prosperous year.